Pages

Thursday, December 24, 2009

Where Cool Waters Flow

Grand Lake Stream is where the Grand Laker canoe was born. This is a large, square-stern, cedar-and-canvas canoe designed for use with a small outboard on the transom.

I haven't yet read Where Cool Waters Flow, but it's on my reading list.

Tuesday, December 22, 2009

Dugouts on Postage Stamps

Hjortspring Boat an Expanded Dugout

Having subsequently read Basil Greenhill's Archaeology of the Boat

Friday, December 18, 2009

Paddle Blog

Murat, a Toronto-based blogger, makes lovely paddles that sometimes transcend mere functionality and experiment with indigenous and/or historic designs and patterns, often interpreting those influences in modern and creative ways. What's different and refreshing is that many of these "art" paddles are not like the hokey, tacky paddles with paintings of wolves or trout on the blades. I've never seen anyone actually use one of those "illustrated" paddles, and if I did, I'd probably think the less of him. I mean, if you're out in the wilderness, why the hell do you need a picture of wildlife on your paddle? But if I saw someone using one of Murat's creations, I'd only admire it, the same way I might admire a nicely-made bark canoe actually being used.

Murat doesn't confine himself to his own paddles, or to paddles at all, in his blog. He recently did a series of posts on the restoration of an old canvas canoe-pack, and he discusses other topics of interest to canoeists of a traditional or historical bent.

I'm experimenting with a new Amazon Associates feature that makes it easy to insert product links into the body of a blog post. Feel free to comment if you think the Amazon link is intrusive, not a problem, or whatever. Thanks.

Finally, this new Amazon feature seems to have made Blogger's spellchecker disappear. Until I find it again, please forgive typos. Thansk!

Tuesday, December 15, 2009

Sabani Sailing

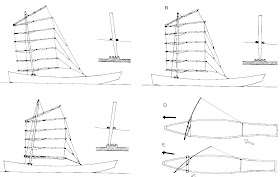

As elsewhere in the booklet, the English text is rather deficient. I'll present it anyway, hoping that some reader can make better sense of it than I can:

How to mast or how to make sail differs according to the strength or direction of the wind.The angle of a mast is adjustable by changing the position of HAIUSHIMI [i.e., mast step]. [Of course, the mast step doesn't move: it's the position of the mast in the step that changes.]

When the wind is not hard , the mast is set up vertically as shown in Fig. B and when the wind is hard, the mast is inclined towards the stern as shown in Fig. C, sometimes with the sail taken in a reef by one FUZAN's [i.e., batten's] length.

Since the way to mast SABANI is not complicated it can easily meet the change of the winds. Quartering (MASUBI) is easiest for SABANI to sail, with its sail open as shown in Fig. D.

Sailing with wind abeam or quatering (sic) is called USAGIBAI or USAGIBARASHI, then a skipper sits in the middle to draw the boat deep so as not to be driven sideways by the wind, as is shown in Fig. E.

Whew! Hard to make sense of that, aside from the interesting point about the skipper moving forward to try to increase the lateral plane when the wind's abeam. Considering that there's no built-in lateral plane (leeboard, keel, outrigger float, etc.), one wonders how well sabanis go to windward.

I also question the angling of the mast depending on the strength of the wind. I suspect that the real function of the multi-position mast step is to change the fore-and-aft location of the center of effort, as on a windsurfer, to aid in steering -- i.e., tilt the mast forward when heading downwind, and tilt the mast aft when heading upwind.

Sunday, December 13, 2009

Sabanis - Canoes or "Boats"?

The day after Douglas's guest post here, I discovered in my possession a booklet on sabanis which had been loaned to me by my colleague Ben Fuller, curator at Penobscot Marine Museum in Searsport, Maine. SABANI Canoes of Okinawa, by Katsuhiko Shiraishi, appears to have been self-published (in 1985, I believe, but I can't find the data now). The text is in both Japanese and English, and although the English translation is, unfortunately, awful, the illustrations are very nice indeed. (The cover is shown below; all images in this post are from the same source.)

Whether the sabani is a "canoe" or not is debatable. On the pro side of the argument, it clearly evolved from a dugout canoe. The bottom is a massive cedar dugout, to which one side strake is added on each side (plus small partial strakes to raise the freeboard at the bow and stern. As Douglas Brooks noted, the strakes, too, bear a relationship to dugout practice, as they are not milled lumber, but hewed to shape.

Whether the sabani is a "canoe" or not is debatable. On the pro side of the argument, it clearly evolved from a dugout canoe. The bottom is a massive cedar dugout, to which one side strake is added on each side (plus small partial strakes to raise the freeboard at the bow and stern. As Douglas Brooks noted, the strakes, too, bear a relationship to dugout practice, as they are not milled lumber, but hewed to shape.On the other hand, it seems wrong to call anything a canoe that features such massive construction overall, and its shape is hardly canoe-like -- more banks-dory-like in its half-breadths, while the fish-form plan view is unique.

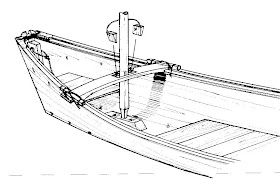

There is a very narrow triangular bow transom that might be considered a stem instead. The stern transom is very close to an equilateral triangle. All pieces are fastened together with dovetail keys, alternating on the inside and outside of the hull. Between each dovetail key is a bamboo nail driven at a very steep angle through one of the exposed plank surfaces so that it edge-nails the bottom to the strakes. (I can't tell if bamboo nails are used similarly at all other joints, or just the bottom-to-side joint.)

There is a very narrow triangular bow transom that might be considered a stem instead. The stern transom is very close to an equilateral triangle. All pieces are fastened together with dovetail keys, alternating on the inside and outside of the hull. Between each dovetail key is a bamboo nail driven at a very steep angle through one of the exposed plank surfaces so that it edge-nails the bottom to the strakes. (I can't tell if bamboo nails are used similarly at all other joints, or just the bottom-to-side joint.)In the image below, the bow is on the left. The stern is considerably higher, to help the stern lift with following waves, according to Shiraishi.

Construction begins by fastening the ends of the strakes together, then forcing the strakes apart amidships, which produces a nice curved sheerline. Then the dugout bottom is carved to shape to sit on the bottom edges of the strakes -- as Douglas Brooks noted, this is opposite to the common procedure for producing an extended dugout, in which the dugout is produced first, as a base, and then strakes are added to build up the sides.

Construction begins by fastening the ends of the strakes together, then forcing the strakes apart amidships, which produces a nice curved sheerline. Then the dugout bottom is carved to shape to sit on the bottom edges of the strakes -- as Douglas Brooks noted, this is opposite to the common procedure for producing an extended dugout, in which the dugout is produced first, as a base, and then strakes are added to build up the sides. On the "it's a canoe" side of the argument, sabanis are paddled, not rowed, as shown below in the picture of a racing version of the boat, used at an annual festival in Okinawa. Note the unusual hand position on the gripless paddle: with the thumbs facing each other. Note also how the flat face of the paddle blade is not the power face.

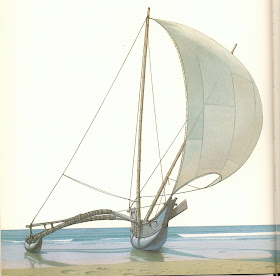

On the "it's a canoe" side of the argument, sabanis are paddled, not rowed, as shown below in the picture of a racing version of the boat, used at an annual festival in Okinawa. Note the unusual hand position on the gripless paddle: with the thumbs facing each other. Note also how the flat face of the paddle blade is not the power face. Shiraishi repeatedly stresses that, due to its narrow beam, the sabani is a fairly unstable boat, prone to capsize especially under sail. (But very pretty under sail, as the image below shows.) It is, however, fairly easy to recover from a capsize. Due to their voluminous wood construction, the raised ends have considerable buoyancy, making the canoe unstable in an inverted position as well. The boatmen turn the boat broadside to a wave and then can easily flip the boat upright. Then they turn it again to face the waves and wait for the bow to lift on a wave while then apply downward pressure on the stern, thus allowing the water to sluice out over the transom. Climb in again, and off they go.

Shiraishi repeatedly stresses that, due to its narrow beam, the sabani is a fairly unstable boat, prone to capsize especially under sail. (But very pretty under sail, as the image below shows.) It is, however, fairly easy to recover from a capsize. Due to their voluminous wood construction, the raised ends have considerable buoyancy, making the canoe unstable in an inverted position as well. The boatmen turn the boat broadside to a wave and then can easily flip the boat upright. Then they turn it again to face the waves and wait for the bow to lift on a wave while then apply downward pressure on the stern, thus allowing the water to sluice out over the transom. Climb in again, and off they go.Thursday, December 10, 2009

Douglas Brooks on Sabanis

I am in Iejima, Japan, a small island that is part of Okinawa, building an eight meter sabani, working with one of the last three builders of these indigenous fishing boats. This work is supported by the Center for Wooden Boats in Seattle, the Asian Cultural Council in New York and the Nippon Foundation in Tokyo. This is my fifth apprenticeship building Japanese boats.

I will keep my comments below very general as the point is to get the reader to go through my blog, where you will find more detail on history, culture, construction techniques, etc.

The sabani is what we would call a semi-dugout type, and in that respect it shares a story with many similar types around the world. As the Okinawans deforested these islands the timber required to make dugout canoes became increasingly difficult to find, hence the move toward a plank-built boat that still retains some of the characteristics of the dugout. So the boat we are building has a four inch thick bottom that we have shaped from three timbers, joined together with butterfly keys and bamboo nails.

Bob made a very interesting observation that sabani are built upside down, with the side planking first, and then the dugout bottom dropped on top. This is opposite of any semi-dugout traditions that either of us know, which start with the hollowed bottom and then add the side planks. It's also odd given that throughout the rest of Japan it's absolute law that boats are built right side up. I will try to ask my teacher what he thinks of this.

Most of the techniques are familiar to me from my other work in Japan, but I wanted to study sabani in part because of the fastening techniques. I already have several blog posts up about the huundu, or dovetail keys, so I won't belabor that here. There will be more postings to come as we continue to use these fastenings to assemble the boat. I am certain that they are a holdover from the days of dugouts, and iron fastenings would have initially been very expensive. I am also finding that while we install them using only hand tools, it is not a slow process, so it all makes good sense, even today.

There are other dugout and semi-dugout traditions in Japan, particularly in the far north, where some still survive. In the mid-90's I met the last dugout builder of Akita Prefecture. He was still fishing every day in a dugout he built in 1965 and he had just built his last dugout as part of a documentary project. On the coast of Akita, Aomori and in Hokkaido you can still find semi-dugout boats in small fishing ports. The first photo shows fishermen out on a winter day in 1965 in their hatahatabune. ("Hatahata" are a small fish, "bune" means boat.) You can just make out the dovetails keys in the bottom, which in a boat this size is six to nine inches thick [Bob here: note too the interesting handles on the oars.]

The next photo is an isobune which means inshore boat. These are still fairly common on the Aomori coast. The bottom is a single timber hollowed out, with a stem, transom, single frame and plank sides added. My teacher in Aomori told me that during his apprenticeship most of his work involved hollowing bottoms of isobune (he quit after three years of this unpaid work).

The next photo is an isobune which means inshore boat. These are still fairly common on the Aomori coast. The bottom is a single timber hollowed out, with a stem, transom, single frame and plank sides added. My teacher in Aomori told me that during his apprenticeship most of his work involved hollowing bottoms of isobune (he quit after three years of this unpaid work).Finally, we have a bekabune, or seaweed gathering boat, that I built in the Urayasu Museum with Mr. Nobuji Udagawa in 2001. It shows the standard Japanese construction method, firmly fixing the bottom of the boat to low blocks on the shop floor braced overhead, then building the boat right side up. Props are used in lieu of clamps to hold the planking in place for fastening. The planks are edge-nailed to each other using special tools and nails. More information about Japanese boat building can be found at my website. Feel free to contact me via the website or to leave comments on my blog, The Sabini Project.

Back to Bob now.

Back to Bob now. I recommend Douglas's blog -- good photos and good writing, with interesting observations on the apprentice system and other aspects of culture in Japan.

A few more items that Douglas noted in our correspondence:

- The side planks of the sabani shown under construction in his blog are not standard milled lumber. "Don't let those side planks fool you, they are CARVED. We started with 2+" thick planks and hollowed about half of the volume out of them on the inside, leaving material for thwart risers and left full thickness at the stem and transom."

- On the dugout-style bottom: "My teacher has specifically talked about the thick bottoms as giving these boats their stability. I have roughly calculated that the bottom alone (it's long and very narrow) represents between 40-50% of the weight of the entire boat."

- And regarding my earlier post on sabanis, which stated that the helmsman sits in the front of the boat: "I suspect is a mistake made by the Japanese writer. It just doesn't make any sense at all. And I have yet to see a sabani or harebune with a helmsman forward. By the way, those festival boats are not strictly speaking sabani, at least not today. They are plank built and considered different from sabani among the old-timers."

Tuesday, December 8, 2009

Plywood "log boats"

Reader "Edwin" left a comment on my previous post about Tlingit log canoes that I thought worthwhile highlighting here, since many of us don't read comments. He draws our attention to Applegate Boatworks of Veneta, Oregon, which, along with the usual boatbuilding services on conventional western-style boats, also builds canoes that resemble the large cedar dugout canoes of the Pacific Northwest. The corker, however, is that he builds them out of plywood, using the "taped seam" (a.k.a. stitch and glue) method. (In reality, it's even stranger: the basic hull is plywood, while the ends are solid cedar, so they can be carved to replicate the shapes of the originals.)

Reader "Edwin" left a comment on my previous post about Tlingit log canoes that I thought worthwhile highlighting here, since many of us don't read comments. He draws our attention to Applegate Boatworks of Veneta, Oregon, which, along with the usual boatbuilding services on conventional western-style boats, also builds canoes that resemble the large cedar dugout canoes of the Pacific Northwest. The corker, however, is that he builds them out of plywood, using the "taped seam" (a.k.a. stitch and glue) method. (In reality, it's even stranger: the basic hull is plywood, while the ends are solid cedar, so they can be carved to replicate the shapes of the originals.)They actually look pretty cool, and the stated purpose is to give people some of the experience of the native craft at reasonable cost and accessibility.

Thanks for the link, Edwin.

Edwin maintains Dark Ages Boats, which I've only just begun to look at but which looks very cool and has some bearing on what we call Indigenous Boats. I'll be spending more time there and may report back in the future.

(Photo from the Applegate website.)

Thursday, December 3, 2009

Great Tlingit Dugout Canoe

Here's a nice blog about a beautiful red cedar canoe in the Tlingit style, built as an educational project by a group of young First Nation people in the Yukon under the guidance of Tlingit Master Carver Wayne Price.

Here's a nice blog about a beautiful red cedar canoe in the Tlingit style, built as an educational project by a group of young First Nation people in the Yukon under the guidance of Tlingit Master Carver Wayne Price.Wednesday, December 2, 2009

Where to Get Your Canoe Fixed or Built

This link might come in handy to some readers: The Wooden Canoe Builders’ Guild.

This link might come in handy to some readers: The Wooden Canoe Builders’ Guild.According to the website, "The Wooden Canoe Builders’ Guild was formed in 1997 to serve the collective needs and interests of builders and restorers of cedar canvas and woodstrip epoxy watercraft and to foster public interest in and knowledge of such watercraft." There's a good list of members, with their specialties listed, some worthwhile articles on canoe care and construction, and an impressive description of the construction standards that guild members must adhere to when building canoes.

Monday, November 30, 2009

Canadian Canoe Museum Photos

|

| Canadian Canoe Museum Nov. 2009 |

Thursday, November 26, 2009

Canadan Canoe Museum - Awe Inspiring

immense storage areas by general manager John Summers. About 500 canoes in storage! A real privilege and an awe-inspiring experience. I'll post in more detail later, but just wanted to post a photo or two and report my immense good fortune. Anyone who has the opportunity to see this special museum should do so -- Peterborough is about 1.5 hours outside of Toronto.

immense storage areas by general manager John Summers. About 500 canoes in storage! A real privilege and an awe-inspiring experience. I'll post in more detail later, but just wanted to post a photo or two and report my immense good fortune. Anyone who has the opportunity to see this special museum should do so -- Peterborough is about 1.5 hours outside of Toronto.

Sunday, November 22, 2009

Some Marine Art I Like

First is this pretty, idealized Sinhalese outrigger, from Bjorn Landstrom's THE QUEST FOR INDIA

Next, from the same book, is a fleet of Chinese oceangoing ships like those on which Marco Polo took the first stage of his voyage home from China some time before the year 1295. The design of the tumblehome is fascinating.

Finally, Egyptian boats from an album of images by Victorian artist and traveler Edward Lear. The images in the album are available as prints from the National Maritime Museum, Greenwich, England. Thanks to Heather Hernandez of the Maritime Compass blog for pointing out this fine resource.

Wednesday, November 18, 2009

More on Greenhill's Planking Theory

Modern lapstrake (clinker) builders set up building forms (or station molds) up on a strongback or backbone, then line off appealing plank shapes, spile the shapes, and then cut the planks to fit properly on the form. This presupposed the existence of carefully drawn plans that can be scaled up to full size, and/or accurate tables of offsets. The traditional clinker builder, in both the Western and non-western traditions, had no such plans or tables -- nothing upon which to base station molds. It was the plank shape that came first, and the boat took shape as those planks were assembled. While most builders relied on memory to copy the plank shapes of their teachers, it must have taken an extraordinary mind to modify the shape of a hull for any reason, for this would require visualizing the shapes of the planks needed to form the hull. Even as simple a boat as a banks dory has very surprisingly-shaped strakes, if you see them "unwrapped" from the hull, and the notion that builders could properly visualize the plank shapes needed for, say, a round-bottomed hull of wide beam, with a hollow entry, spoon-shaped bow, and a tucked-up transom stern -- well, just try and do that without CAD.

But do it they did. Shown below are a couple examples. The first, at the National Maritime Museum (Greenwich, England), was a demonstration to show how it was done without forms. The builder did use a few half-molds, but these were simply held in place by hand, temporarily, to check how the hull was developing. Planks were not bent around them.

The next example is a Bengladeshi boat, similar to the hull shown in yesterday's post. Note the copious use of clamps and shores to hold strakes in place while they're fastened.

The next example is a Bengladeshi boat, similar to the hull shown in yesterday's post. Note the copious use of clamps and shores to hold strakes in place while they're fastened. The following photo shows a typical, mostly frameless, Bengladeshi working boat built by the method shown above.

The following photo shows a typical, mostly frameless, Bengladeshi working boat built by the method shown above. Finally, we see a variety of planking styles used to extend (raise) the sides of a dugout canoe. These same planking methods continued to be used after the dugout base had atrophied into a keel. All are examples of what Greenhill described as "edge-joined" planking and, whether lapped or smooth, were methods used to build shell-built hulls.

Finally, we see a variety of planking styles used to extend (raise) the sides of a dugout canoe. These same planking methods continued to be used after the dugout base had atrophied into a keel. All are examples of what Greenhill described as "edge-joined" planking and, whether lapped or smooth, were methods used to build shell-built hulls. (All images in this post are from Archaeology of the Boat, by Basil Greenhill.)

(All images in this post are from Archaeology of the Boat, by Basil Greenhill.)

Tuesday, November 17, 2009

Planking: it's more than just carvel vs. clinker

In September, I discussed Basil Greenhill's "four roots of boatbuilding" as described in his Archaeology of the Boat. Another important theme of this book is the typology of boats based on their planking styles. In the Western tradition, we're accustomed to thinking of everything in terms of smooth-skinned versus overlapping planks -- also known as carvel versus lapstrake (a.k.a. clinker). But looking at boatbuilding from a broader cultural perspective, this is not a very useful distinction.

In September, I discussed Basil Greenhill's "four roots of boatbuilding" as described in his Archaeology of the Boat. Another important theme of this book is the typology of boats based on their planking styles. In the Western tradition, we're accustomed to thinking of everything in terms of smooth-skinned versus overlapping planks -- also known as carvel versus lapstrake (a.k.a. clinker). But looking at boatbuilding from a broader cultural perspective, this is not a very useful distinction.Modern builders of traditional western boat types do much of the setup the same way, regardless of whether they're building carvel or lapstrake: first you set up building forms or sawn frames; then you bend planks around the forms or frames. Then if you were using forms, you replace them with frames. But this wasn't always the case. The lapstrake tradition is by far the older one in western culture and, in contrast to modern methods, building forms and sawn frames were not used. This is because builders did not work from plans, and did not envision the boat as a series of sections or half-breadths.

Rather, they viewed the boat as a shell. Plank shapes were the starting point, and through experience, ancient builders could envision how a collection or series of plank shapes would go together to create a boat of a given shape. The planks were, in Greenhill's terminology, "edge-joined" to one another to create the shell or envelope, and only then was an internal structure inserted.

But beware the term "edge-joined" in the paragraph above. These were lapstrake boats, and the planks were not set "edge to edge" carvel-style. The edges did in fact overlap, lapstrake-style. By "edge joined," Greenhill means that the planks are structurally connected to one another to create the shape of the hull. This, then, is a clear contrast to carvel planking, in which the planks are not attached to each other at all but, rather, are attached to the frames for structural integrity.

So Greenhill largely divides plank-built boats into edge-joined, i.e., "shell-built" hulls, and non-edge-joined, i.e., skeleton-built hulls. This proves to be a far more useful way of looking at boats archaeologically and cross-culturally, because many cultures use (or used) edge-joined planking methods that result in a smooth outer skin. This involves the use of a variety of overlapping methods, one of which is shown below in images from Greenhill's book.

The images show a common planking method of Bengladesh. Note the full-length rabbet between the planks, which are joined by iron staples set into mortises on both sides. After the entire shell is thus assembled, frames are added to the inside. As shown in the photo, frames across the bottom (i.e., floors) often do not even touch frame members up the sides. The shell provides the majority of its own structural integrity, and the frames are reinforcements, but not essential structure as in a carvel hull's skeleton.

The images show a common planking method of Bengladesh. Note the full-length rabbet between the planks, which are joined by iron staples set into mortises on both sides. After the entire shell is thus assembled, frames are added to the inside. As shown in the photo, frames across the bottom (i.e., floors) often do not even touch frame members up the sides. The shell provides the majority of its own structural integrity, and the frames are reinforcements, but not essential structure as in a carvel hull's skeleton. Greenhill diagrams about two dozen shell-forming methods (unfortunately, the book's graphic doesn't scan well for the web), with a great variety of plank-joint styles (e.g., rabbeted/smooth- skinned, normal lapstrake; reverse-lapstrake [in which the lower plank's upper edge is outside of the upper plank's lower edge]; strip-planking, bevelled/smooth-skinned, flat, flush smooth skinned, and more) and fastening methods (e.g., mortised staples, sewing or stitching, edge-nailing or dowelling, etc.). It's clear that the majority of plank-built boats in what I refer to as indigenous traditions rely on edge-joining/shell-built technology.

Viewing all plank-built boats from this perspective opens up one's understanding of boatbuilding far beyond the carvel-vs.-clinker duology. One can therefore see the Chesapeake Bay log canoe (western culture, yes, but outside the norms of the western boatbuilding tradition) in a new light: although the topsides planks conventionally meet the boat's stem and stern, the bottom planks run parallel to each other, their ends curving up to meet the bottom edge of the lowest topsides plank rather than curving inward toward stem or sternpost. The evolution of this type makes sense: originally it was truly a log canoe. It was expanded laterally by adding additional logs; the logs were hollowed out and, over stages, became not hollowed logs but planks -- but they were still joined edge-to-edge to make the shell. Eventually, topsides strakes were added in what has now become the traditional carvel style.

Friday, October 2, 2009

Jewel of Muscat Near Launching

Wednesday, September 23, 2009

The Four Roots of Boatbuilding

Old though it is (1976), Basil Greenhill's Archaeology of the Boat

Old though it is (1976), Basil Greenhill's Archaeology of the BoatGreenhill identifies four "roots" of boatbuilding, from which, he argues, all boat types derived:

1. Rafts and raft-boats: a craft which is not watertight -- i.e., it does not enclose air. Its buoyancy comes from the buoyancy of the boatbuilding material itself. A "raft-boat" is basically a raft with a more or less boat-like shape, i.e., pointy at the bow, like the Brazilian jangada. Raft building materials include logs lashed together, bundles of reeds, and air bladders like inflated animal skins. Greenhill states that Chinese sampans may have evolved from rafts. The paired illustrations shown below are an intriguing bit of evidence to this effect.

Above: a sophisticated Chinese sailing raft, with movable daggerboards and capable of upwind sailing.

Above: a sophisticated Chinese sailing raft, with movable daggerboards and capable of upwind sailing.Below: the bottom of this sampan shows similarities to the raft above and lends credence to the theory that the sampan is one of the few extant boat types that derived from rafts, rather than dugouts.

(All images in this post are from Greenhill's book. All may be clicked to magnify.)

2. Skin boats: in which a skeleton built of sticks is covered by a skin, either animal skins or a waterproofed fabric. Obvious indigenous examples include kayaks, umiaks, coracles, and curraghs. These evolved into a very limited number of modern types such as folding kayaks and canoes. (Greenhill states that the basket-boat is a variation of the skin boat. The book, a survey, doesn't give evidence for this conclusion, and I'm skeptical that they share a common ancestry. I suspect that the basket boat may be a fifth, very small, root, which wasn't further developed.)

3. Bark boats: the American birch bark canoe being the obvious example, and the only well-developed one.

4. Dugouts. A hollowed log in its earliest iterations, the dugout was elaborated and expanded upon in many directions, and evolved into most of the boat types we know today. The evolutionary process took place in many phases, at many times and in many places, and it was far from a smooth, linear movement -- which is why we have such a diversity of plank-built boats today.

A log that has simply been hollowed out has limited seaworthiness and, as they get larger, they become quite unhandy. Simply but, they're too narrow and too shallow. The first stage of evolution, then, was the "expanded" dugout, in which the hollowed log is heated from the inside (top image in the graphic below) , usually with boiling water, and its sides are then forced apart with shores (left bottom). Not only does this increase the beam, but it forces the ends upward, creating a true "boat" shape that is both more aesthetically pleasing and more seaworthy.

The process does, however, make the boat even shallower (i.e., reduces freeboard), so the next step is to "extend" the hull by the addition of a single plank on each side (right bottom). Different cultures invented different methods of fastening the plank: pegs, stitches, mortise/tenon joints, dovetail inserts, and so on.

Top: dugout heated to soften. Left bottom: expanded. Right bottom: extended by the addition of a strake.

Top: dugout heated to soften. Left bottom: expanded. Right bottom: extended by the addition of a strake.

This was probably how plank-built boatbuilding got its start in Western culture. But since evolution doesn't progress linearly, it didn't work that way in all cultures and at all times. The Polynesian outrigger canoe, for example, is a dugout that is often extended but not expanded. The large cedar dugouts of the Pacific Northwest were expanded but often not extended. Of course, the Indians of the Pacific Northwest had enormous trees with which to work.

The balam (below), from the Bay of Bengal, is a sewn boat that Greenhill calls the "ulimate development" of the expanded-and-extended dugout. Based on a dugout hull that essentially acts like a backbone keel, it has been extended by the addition of five strakes.

A balam from the Bay of Bengal

A balam from the Bay of Bengal

Wednesday, September 16, 2009

National Maritime Museum, Cornwall

Welsh Coracle (photo National Maritime Museum Cornwall)

Welsh Coracle (photo National Maritime Museum Cornwall)Thursday, September 10, 2009

Does This Look Like a Spam Blog?

I was just notified by Blogger that this blog is a suspected spam blog. I had to submit a request for a human review (apparently, the initial scan is performed by a robot with the intelligence of Glen Beck), and I guess I passed the test, because I seem to be back in business. But just in case I get locked out and they slap manacles on Indigenous Boats, please inform Blogger that this blog is not spam, and that you are a real human reader who doesn't object to its content.

Many thanks,

Bob

Friday, September 4, 2009

Another Tub Boat, and Some Corrections

G.R.G. Worcester's monumental The Junks and Sampans of the Yangtze

G.R.G. Worcester's monumental The Junks and Sampans of the Yangtze

Tuesday, September 1, 2009

Traditional Boatbuilding in Japan

Boat plan from The Tub Boats of Sado Island, by Doug Brooks. Available from the author. Click to enlarge.

Boat plan from The Tub Boats of Sado Island, by Doug Brooks. Available from the author. Click to enlarge.Doug Brooks, the American expert in traditional Japanese boat construction, gave a lively, fascinating talk a few weeks back at Carpenter's Boat Shop in Pemaquid, Maine, speaking about tub boats and other types, as well as the state of traditional boatbuilding in Japan and the apprenticeship system there. What follows are notes and observations based on his talk, not a coherent treatment of a single subject.

Techniques

- Japanese boatbuilders generally use no clamps. They rely on the Spanish windlass and a multitude of props against ceiling, floor, and walls to hold things in place for fastening.

- Most strakes are edge-nailed to one another. An angled mortise is cut into the outside of the upper plank, near its bottom edge. Special boat nails are used: flat galvanized steel, somewhat curved, with an offset head. These are now hard to obtain, since traditional boatbuilding is virtually dead in Japan. The mortise is then sometimes covered with a small rectangle of sheet copper.

- Although planks are edge-joined, there is no caulking. Much effort is put into making a perfect wood-to-wood fit by "clamping" (see above) the two mating boards edge-to-edge, then running progressively finer saws between them. This is an exacting and lengthy process, but very effective. Japanese boatbuilders consider any seepage whatsoever that occurs on launching to be shameful, and they view the Western practice of caulking joints with suspicion -- viewing it possibly as evidence of a carpenter's inability to make a watertight joint through a good wood-to-wood fit..

- Most building is done in Japanese cedar. Little hardwood is available or used. Planks may be pre-bent over fire (live or charcoal), but not with steam or boiling water.

- Traditional craftsmen use few drawings and patterns, and those drawings which exist tend to be purposely incomplete, in order to protect "trade secrets." Patterns are usually just small bits of wood that show the proper angle for a particular joint. Everything else is in the builder's head.

The Apprentice System

- Students served a very lengthy apprenticeship -- as much as seven years. Even so, the master builder spent almost no time on instruction. The apprentice was expected to humbly absorb knowledge through observation...and through a process known as "stolen knowledge." If the master wouldn't explain a given detail, the apprentice was almost expected to sneak into the shop some night to copy patterns or otherwise figure things out. Although the objective was to duplicate the master's work, even so there was a saying, "The true craftsman must go beyond his master," improving on his methods in some respect.

- With the exception of Doug's book The Tub Boats of Sado Island, there are no comprehensive books in English on traditional Japanese boat building. Even in Japanese there are very few published works detailing the craft, and most of those that exist are monographs published by local museums, without national distribution. Neither are there any schools of traditional boatbuilding. Plans for traditional boats are not available. There are essentially no hobbyist-builders of traditional Japanese types.

- This is all partly due to the traditional secrecy of the master builders. They hoarded their knowledge, giving it up even to their own apprentices reluctantly. They would never commit designs to paper, fearing theft. Even today, with the last, aged builders passing from the scene, few will reveal their secrets. And given Japan's drive toward modernity following the Second World War, there were few young men interested in pursuing a traditional craft, and even fewer willing to serve the very lengthy apprenticeship required.

Left: a pattern for the inside and outside curves of tub-boat planks and the angles of plank edges. Right: Japanese plane.

Left: a pattern for the inside and outside curves of tub-boat planks and the angles of plank edges. Right: Japanese plane. Red-headed item: an ink-line. The Japanese equivalent of a chalkline. The cross-shaped item is a tool for splitting bamboo lengthwise. The two interlocking pieces are wedge-shaped. Split bamboo is braided into hoops to hold tub boats together. (See drawing at top and next photo.)

Red-headed item: an ink-line. The Japanese equivalent of a chalkline. The cross-shaped item is a tool for splitting bamboo lengthwise. The two interlocking pieces are wedge-shaped. Split bamboo is braided into hoops to hold tub boats together. (See drawing at top and next photo.) A Japanese pull-saw, and a miniature example of the braided bamboo hoop for a tub boat. Doug says that braiding the hoops is the most difficult part of building a tub boat. They have to be just the right circumference -- to within a couple eighths of an inch -- in order to fit properly and provide the pressure needed to hold the boat together.

A Japanese pull-saw, and a miniature example of the braided bamboo hoop for a tub boat. Doug says that braiding the hoops is the most difficult part of building a tub boat. They have to be just the right circumference -- to within a couple eighths of an inch -- in order to fit properly and provide the pressure needed to hold the boat together.