|

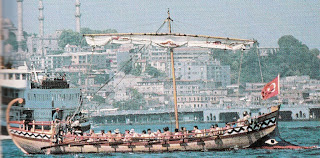

| The boom Sohar under main and mizzen. She also flew a jib. (Click any photo to enlarge.) All photos are from The Sinbad Voyage except where noted. |

In 1980, Tim Severin built and launched the dhow Sohar, a twin-masted boom of sewn-plank construction. Although he referred to the expedition for which Sohar had been built as The Sinbad Voyage , in honor of that legendary -- and probably fictional -- Arab sailor, Severin's objective was to complete a historically accurate voyage of reenactment on the well-documented trade route from the Middle East to China followed by Arab merchants in the 8th through 10th centuries. (I've written previously about some of Severin's other voyages of reenactment: The Brendan Voyage; The China Voyage; and The Jason Voyage.)

, in honor of that legendary -- and probably fictional -- Arab sailor, Severin's objective was to complete a historically accurate voyage of reenactment on the well-documented trade route from the Middle East to China followed by Arab merchants in the 8th through 10th centuries. (I've written previously about some of Severin's other voyages of reenactment: The Brendan Voyage; The China Voyage; and The Jason Voyage.)

Dhow is an imprecise term used only by Westerners for Indian Ocean vessels of traditional, mainly Arab or Indian, design. Arabs and Indians never use the term, but refer to a variety of specific craft, distinguished by hull shape and rig, by different terms. Before large commercial sailing dhows essentially disappeared around the end of the 20th century, the boom was one of the more popular types. Booms are distinguished mainly by their long, perfectly straight stem that rakes far forward. They are ketch-rigged, in the sense that they have two masts, the mizzen being ahead of the rudder post. But both masts hoist settee sails, unlike any Western ketch. (See a discussion of the settee sail.)

|

| Sohar careened to reapply antifouling. This shot gives a good sense of her underwater shape, and the plank stitches can be plainly seen. |

Whether booms existed in the 8th-10th centuries is not certain (the evidence Severin cites is not convincing), but Arab long-distance trading vessels of that period were certainly built shell-first and without forms or pre-set frames, with their planks stitched together. (Here's a view of a 9th century Arab dhow based on more recent research.)

Sohar was 80 feet LOA, 63 feet LWL, 20 feet in beam, and 6 feet in draught. The backbone -- the timbers for which were all single, full-length pieces -- consisted of a 52-foot keel, 12"x15" in section, a 36'3" stem, and an 18' sternpost. I'll allow Severin to describe the planking:

Each strake was 8-12 inches broad, and between 2 1/4 and 3 inches thick depending on its position. No stealers were used. The strakes were normally divided into four or five sections, between 5 and 15 feet long, butted end to end with tongue and groove joints. The edge-to-edge surfaces between the strakes were flat; that is, there was no step or groove, though every 18 inches or so a locator dowel was used. The entire form was held together with coir stitching, done with four-strand cord. Stitch holes were approximately 4 inches apart, and placed 2 inches from the edges of the strakes.

As is typical in traditional forms of shell-first construction, the planks were cut to the needed shape without patterns or spiling: the builders simply know what shape to cut and how it will lie when bent and twisted into position. Planks were gotten out and fined up with soft iron chisels. Getting the mating surfaces to lie flush against one another to the required accuracy of 1/64" inch necessitated several trial fittings for every plank. Severin does not say whether the thick planks were steamed or fire-bent, but it was evidently hard and time-consuming work getting them into place.

No caulking in the regular sense was used. Instead, long narrow bundles of coir (coconut husk) fiber, which the builders called pythons, were placed along the interior seams, and the plank stitching wrapped around them, compressing them against the seams and holding them in place. To quote Severin on the installation of the first garboard section:

|

| Lashing the first garboard plank to the keel. The worker at the bottom is using a short pole as a lever to tighten the lashing. The "python" can be seen at the left, just inboard of the plank. |

When Kasmikoya, the senior ropeworker, was ready, he divided his men into pairs, an inside man and an outside man. Each pair worked at passing a strand of the finest-quality coir cord out through a hole in the plank, back through the opposite hole in the keel, round the python and out again. There the outside man took a turn of the cord around his lever of stout wood, put his feet against the hull, leaned back, and hauled the string as tight as he could. On the inside, his partner tapped on the string to help it tighten.... Three times, stitch and overstitch, they lashed together plank, keel and python until finally the last stitches were plugged with little tufts of raw coconut fiber.

|

| The complete garboard, installed; the next plank clamped in place and ready for stitching to begin. |

After five strakes were in place, floors were installed, again lashed in place through holes bored in the planking. Partial frames were added in sections as the planking progressed. (Stitched hulls must be built shell-first; pre-set frames would make it impossible to stitch planks together.) Floors, lower frames and upper frames were all free-floating: that is, although they overlapped in height, they were not connected to each other. The framing was neatly gotten out on Sohar, unlike the frames on working dhows which were often hewed flat only on the bottom, and left entirely raw on their exposed surfaces. Floors and frames were also neatly notched so that lashings lay flush with, or recessed below, the surface, protecting them from abrasion.

The exterior, below the waterline, was coated with antifouling made from lime mixed with mutton fat. Even in the teredo-infested Indian Ocean, this was entirely effective.

|

| Applying lime-and-fat antifouling by hand. (The vessel shown is not Sohar.) One can only imagine what this does to your skin. |

All interior surfaces were saturated with vegetable oil, a process that prevents the lashings and pythons from rotting if repeated every four to six months. But the veggy-oil coating had a serious downside: it generated copious amounts of hydrogen sulfide, so noxious that it caused sore throats, made eyes sting, and corroded electronics and other metals. So bad was the "bilge gas" that the crew avoided spending time belowdecks except in the worst weather.

|

| Oiling the interior. Note how the lashings are neatly set into the frames, and how the frames are also notched over the pythons, which run lengthwise over the plank seams. The floors and partial frames are not fastened to one another -- indeed, they do not even touch. |

Archaic though it may be, the stitched planking method employed on Sohar was entirely effective. The ship leaked no worse than many another wooden ship, and it successfully completed its 6,000-mile voyage without serious mishap, and in good condition.

by Tim Severin. Click image to enlarge.)

by Tim Severin. Click image to enlarge.)